How It's Done...

Getting Sized and Making Your Ring...

All custom rings are commissioned in order to guarantee a perfect fit upon final delivery. The following process has proven to be very reliable in creating a highly personalized ring that will fit perfectly. A deposit of 1/3 the total price gets the process rolling. The final balance is not due until the ring is 100% completed and ready for final delivery.

1. A sizing set is sent to the customer along with a prepaid return envelope to return them. Sizing sets are custom made, in-house, to the same standards of finished rings. If you're looking for a 12mm wide band, you will receive a 12mm wide sizing set eliminating all guesswork in sizing.

2. When the ring blank is made to the requested specifications, upon request it is sent to the customer for a test fit and a prepaid return envelope is include to return. (This step is no longer necessary with the custom made sizing sets shown above and will help expedite final delivery of the finished ring when skipped.)

3. Adjustments are made to the ring and, if requested, shipped back to the customer for additional test fitting.

4. The ring is engraved upon return.

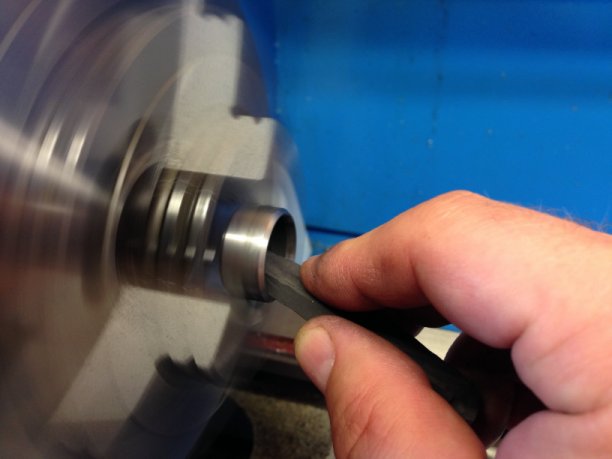

Damascus steel and titanium rings are made in-house on this 12X28" lathe. As soon as an accurate ring size is determined, a ring is made to the specifications requested including width, thickness, domed or pipe cut (flat) profile and most importantly the size with comfort fit.

Accuracy of sizing sets vary from manufacturers. To eliminate this margin of error, exact inner diameters are used when creating a ring. Below a true size 11 (0.81") is being bored through a piece of stock.

When a ring blank is made, it is sent to the customer for a trial fitting. We want to be absolutely certain that the ring is going to fit perfectly before it is engraved. Below, a ring has been bored up 1/4 of a size, the comfort fit adjusted accordingly and the final polish using oil stones and sand paper is applied for a perfect finish.

Carving out the design on a 12mm wide damascus wedding band...

Deeply engraved to last.

Shaping and smoothing the design using oil stones...

(Photo taken through microscope eye piece)

Finished ring...

Damascus....what is it? It's 2 different grades of metal that are forged together. Patterns created during the forging are an artform. Historically, the process was intended to create a stronger steel but today has evolved into an art.

Pipe cut and domed profile 10mm wide bands...

Below is the above domed ring blank fully hand engraved in the usual sculpted scroll pattern...